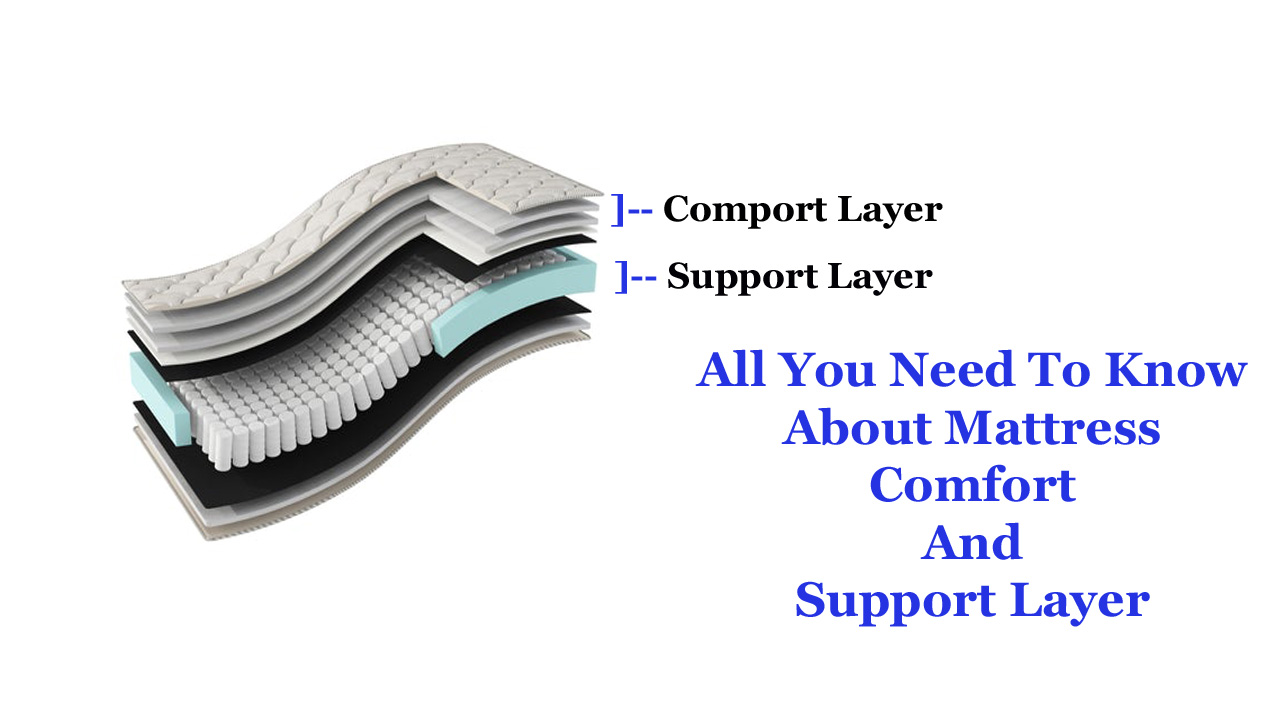

Do you know about the various layers with which a mattress is manufactured?

Do you have any idea that those layers can be divided into two major parts- comfort and support layers?

If not, then it’s time to learn more about what these comfort and support layers are and why they are categorized in such a way. When you are choosing the mattress, you check the materials with which the product is made. However, you don’t focus on whether the comfort and support materials are appropriate for fulfilling your requirements or not.

On this account, we have presented here a complete mattress comfort and support layer guide, which will help you understand these layers and their functions, types, etc.

Contents

What are the comfort and support layers in a mattress?

The main two functions are to provide you comfort for sleeping in a luxurious and posh manner while supporting your body weight and reducing the pain in the muscles and bones simultaneously.

To help the mattress perform both these actions properly, manufacturers include comfort and a support layer.

- Comfort layer: This particular layer is added only to comfort the sleepers once their body hits the bed. Furthermore, they are less firm and quite lightweight so that you can feel the cosiness.

- Support layer: From the name itself, you can understand that the layer is mainly added to provide support to the above materials in the mattress and maintain the skeletal posture of the sleepers.

With what materials comfort layer is manufactured?

A support layer is formed from denser and firmer materials that can provide both support and stability to the upper comfort layers. Following materials are usually considered to be the perfect option for support.

- PU foam is preferred due to its extreme softness and posh feel.

- Memory foam is also considered a comfort layer since it provides bounciness and relieves pain from the muscles and the spine.

- HR soft foam is also added in certain mattresses with a huge bounciness and a soft feel.

- Coir is sometimes considered as the comfort layer based on whether the fibres are curled too much or not.

What materials are used for manufacturing the support layers?

A support layer is formed from denser and firmer materials that can provide both support and stability to the upper comfort layers. Following materials are usually considered to be the perfect option for support.

- HD or High-density foam is added because of its hardness and high firmness level.

- HR foam is added to support the memory foam in almost 70% of the mattresses to increase the bounce and support.

- Rubberised coir supports the above layers in a mattress having overall firmness between 4.5 to 6.

- Rebonded foam is usually used when there are multiple soft and comfort layers added to the mattress.

Comfort Layer Vs Support Layer

| Attribute | Comfort layer | Support layer |

| Temperature regulation | Can regulate the temperature with ease due to the air pockets present in the layers as well as due to the inclusion of gel-based cooling material in some products | Unable to regulate temperature due to high density |

| Firmness | Less firm with the value ranging between 3 and 5.5 | It is highly firm to add support to both the comfort layers and the sleepers |

| Motion transfer | Plays a pivotal role in reducing the motion transfer, thanks to the special design of the comfort layer | Does not have any role in preventing the motion transfer |

| Conforming | Conforms according to the applied heat and pressure on the upper surface | Does not conform according to the applied pressure and heat |

| Durability | Less durable due to lower firmness value and hence, can easily sag underweight. | It is highly durable due to its high density and weight so that it won’t sag too soon. |

Conclusion

You now have an idea about the support and comfort layers in any mattress and their function. However, since both these layers of material vary from basic PU foam to advanced rebonded foam, you must choose them carefully. If you want plushness, you must go with the soft comfort materials, while for having better body support, the mattress should have firmer support material.